The whole filter is composed of several filtration units in parallel. The filtered liquid is used for back washing and regeneration. When conducting back washing on one filtration unit, the other units shall be used for normal filtration.

APPLICATION CONDITIONS

The filter could be used to purify liquid medias such as gasoline, heavy-load coked gasoline, diesel, residual oil, sewage and other medias.

ADVANTAGES

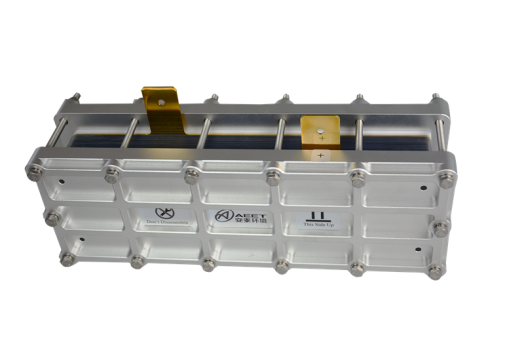

Stainless steel wedge filter cartridges are used in the filter, which feature good mechanical rigid, resistance to differential pressure, excellent regeneration perfor-mance and easy washing. The whole equipment has such features as small space occupation, convenient installation and operation, low construction cost, small waste oil discharge and high automation.

WORKING PRINCIPLE

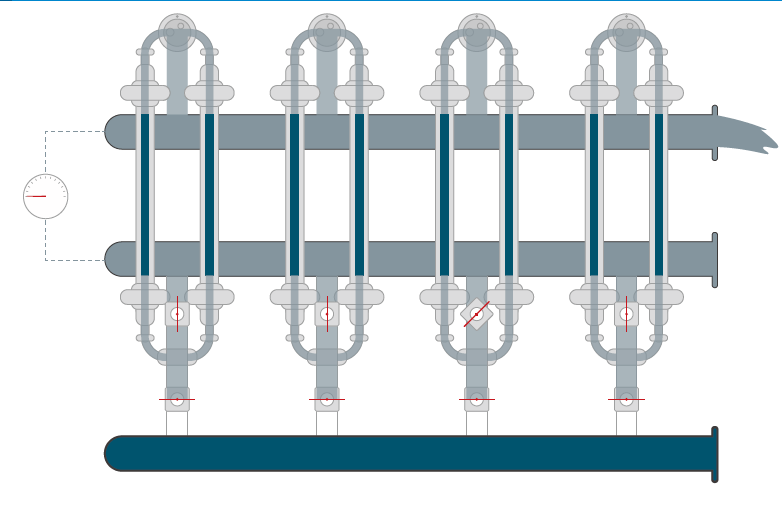

Tube-Type Automatic Back Washing Filter is composed of more than 3 filtration units in parallel.

When the fluid is passing through filter cartridges, the solid particles will be retained on the outer surface of the filter cartridges to form filtration cakes, increasing the differential pressure before and after the filtration. When the differential pressure reaches preset value, the program controller will be activated to conduct automatic back washing in the following way:

The whole facility could use the filtered clean liquid for back washing to remove the filtration cakes deposited on the outer surfaces of filter cartridges. During back washing, the control program will control the feeding valve and discharge valve of one group of filters to cut off the feeding line and open the discharge line of the filter group to rapidly remove the filtration cakes under the pressure from cleaning liquid and discharge the waste oil into the sewage and recovery channel. Then the discharge valve will be closed and inlet valve will be opened to start the normal filtration operation.

The program controller will wash the filters group by group in specified order. During the back washing of one group, the other groups will be still used for normal filtration operation.

SCHEMATIC DIAGRAM

APPLICATIONS

+ Filtration of raw oil in diesel hydrogenation treatment facility

+ Filtration of raw oil gasoline hydrogenation treatment facility

+ Filtration of jet fuel

+ Filtration of raw oil in coked gas oil treatment facility