Metallurgical equipment

To today, the Metallurgical Equipment Department of AEET has successfully delivered hundreds of rolling mills and Hydraulic AGC systems.

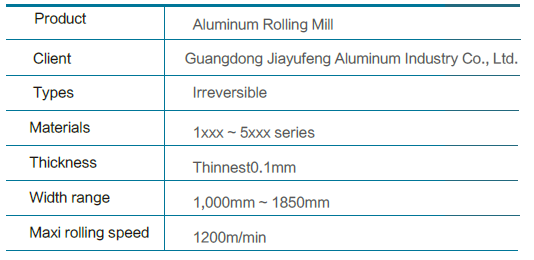

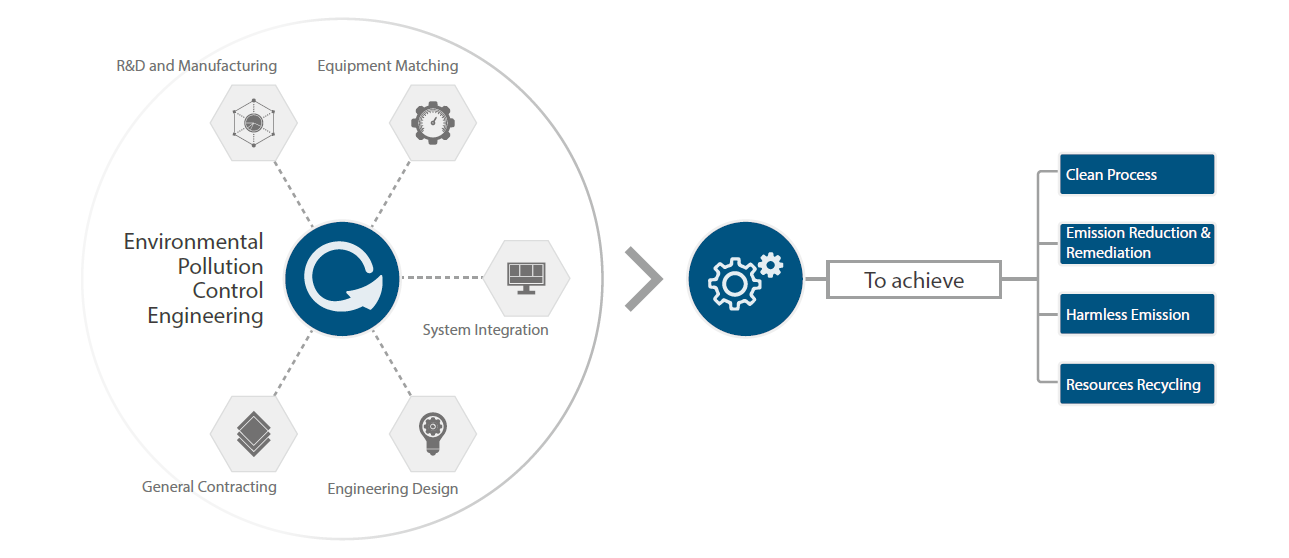

Our advantages include clear process thoughts and good knowledge in material properties. With our profound R&D strength, excellent performance and good reputation, our company has developed into an integrator of mid- and high-end metallurgical equipments in China and an integrated designer of new processing equipments.

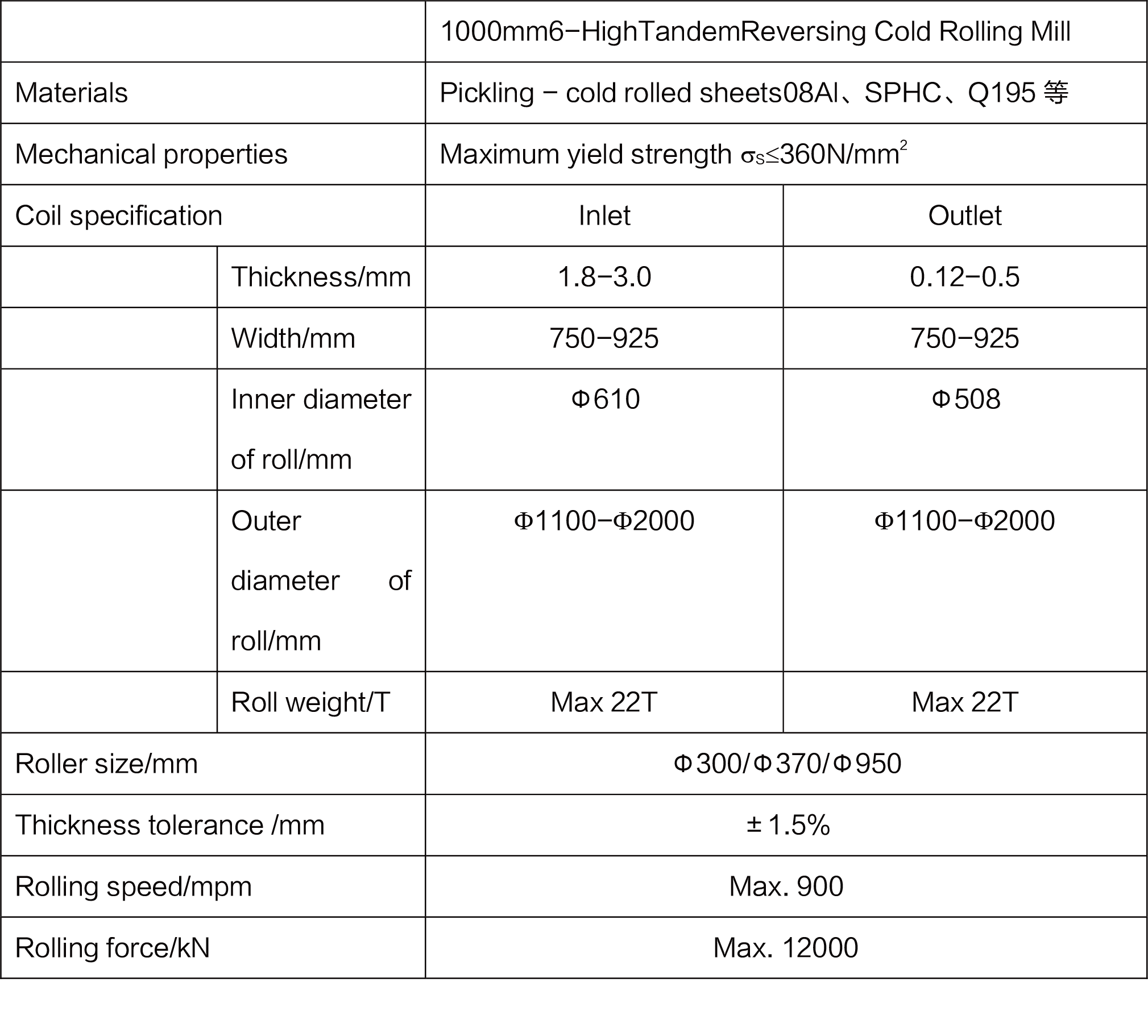

Shandong Shenglong 1000 rolling mill is equipped with high-power main motor and high-tension coiler. The raw material with thickness of 3.0mm x 925mm is steadily rolled for 6 passes to produce the finished product with thickness of 0.12mm x 925mm without intermediate annealing. Therefore, the production cost is greatly reduced by customers. The project is running well at present.