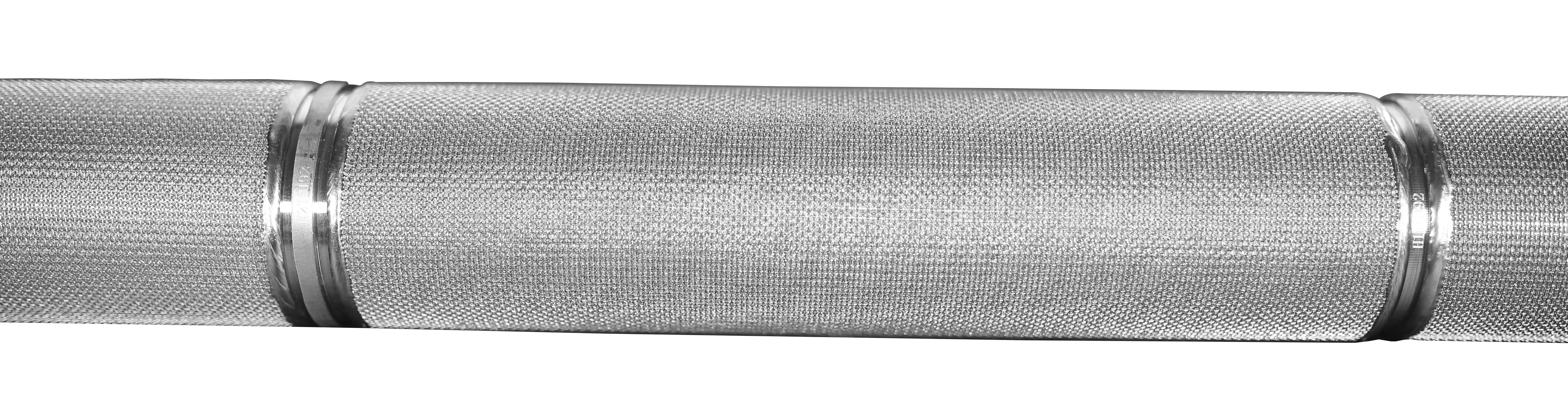

Sintered Metal Mesh Material and Filter Elements

Sintered metal mesh porous material is characterized of simple structure, even mesh aperture distribution as ordinary metal woven mesh, but high strength, good integrity, stable and rigid mesh shape. Further, the material can be customized for its pore size, permeability, mechanical strength, which show excellent comprehensive performance。

FEATURES AND BENEFITS

+ Rigid, stable and even pore distribution

+ Good permeability and low resistance loss

+ Easily cleanable with smooth surface

+ High strength and workable under high differential pressure

+ Extensive materials selection

+ High temperature and corrosion resistance

+ Liable to processing and molding

+ Superior welding performance

APPLICATIONS

Petrochemical: Rectisol process (solid-liquid separation), etc.

Coal chemical: Raw oil filtration, dust collector filter, etc. Shipping industry: Ballast water treatment

Aviation industry: Hydraulic oil filtration

Metallurgical equipments: Fluidizing plate/tank

TECHNICAL SPECIFICATIONS

Materials of Construction:

Stainless steel(310S,316L, 304), Copper Alloy, Inconel、Hastelloy,FeCrAlalloy, etc.

Weldless Dimensions:

Plate max W 1000×L 1200mm

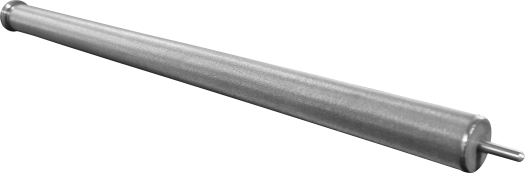

Cartridges Diameter Ф3~100mm, Length ≤1000mm

Operating Performance:

Maximum working temperature: ≤900℃