Construction of Hydrogen Energy Supply System

+ Flexible solutions for different need of H2E applications

+ Key HRS equipments

+ EPC projects for HPU and HRS

+ Technical service for operation & maintenance of HPU and HRS

+ Flexible solutions for different need of H2E applications

+ Key HRS equipments

+ EPC projects for HPU and HRS

+ Technical service for operation & maintenance of HPU and HRS

Construction Materials

Inter-metallic compound Fe3Al porous material instead of traditional ceramic material, characterized with high thermal shock resistance, as well as good compre-hensive mechanical properties, also has high temperature and corrosion resistance, widely used in the process of Shell、U-gas、KBR.

In 2012, Shell authorized AT&M (AEET’ s shareholder) as the manufacturer of its HPHT fly ash filter cartridges.

Features and Benefits

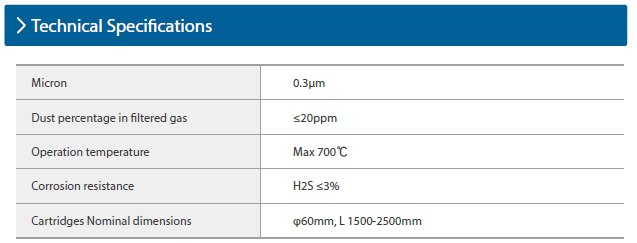

+ High filtration precision and flow rate

+ High temperature and corrosion resistance with super length

+ The switching time for pulse back-blow valve less than 100ms

+ Special software to analyze filter flow and temperature fields

+ Stable and continuous operation

Achievements

Since 2010, AEET’ s Fe3Al filter cartridges have been used in around 46 sets(around 60000 filters) of SCGP device including Shenhua Coal Liquefaction project etc, showing excellent performance in strength, filtration precision, differential pressure and so on compared with imported ceramic filtration candle, with maximum consistent running time over 4 years.

Fe3Al filter cartridges can keep its shape after long-time use with intact surface layer. It’ s repeatedly cleanable as ceramic candles, meanwhile keeping outstanding performance of high precision, flux and mechanical strength.

The metal membrane purification elements and components developed by AEET have won the first prize of the national invention award and many second prizes.

Metal Membrane Micro Porous Material is a kind of Material with super high-filtra-tion accuracy, excellent cleanable ability and relative high permeability due to its small pore size, large porosity and small thickness, and pore size can be 0.1μm even less via composite processing technology.

APPLICATIONS

The purification elements and components have an important role in the purification of hydrogen and its isotope gases, production of solid nuclear fuels, treatment of nuclear wastes and retired nuclear facilities, purification and discharge of nuclear waste gases and the civil nuclear power industry.